close

Filter By

Brand

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.21 1

- 0.22 2

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 11

- 0.51 1

- 0.52 5

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 4

- 0.60 5

- 0.63 1

- 0.64 1

- 0.65 3

- 0.67 3

- 0.68 1

- 0.70 1

- 0.71 3

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 1

- 0.93 1

- 0.94 2

- 0.95 1

- 0.96 1

- 0.97 1

- 0.98 1

- 1.00 21

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 3

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 1

- 1.62 3

- 1.63 1

- 1.64 1

- 1.67 2

- 1.68 1

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 10.60 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 2

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.20 1

- 14.43 1

- 14.54 1

- 14.64 1

- 140.00 2

- 15.00 4

- 15.14 1

- 15.15 1

- 15.50 1

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 1

- 16.05 1

- 16.33 1

- 16.80 1

- 160.00 1

- 17.00 1

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 18.00 7

- 18.08 1

- 18.24 1

- 18.30 1

- 18.46 2

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 22

- 2.02 1

- 2.05 2

- 2.09 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.50 9

- 2.53 1

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 5

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 1

- 20.02 2

- 20.27 1

- 20.34 2

- 20.68 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 1

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 1

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 1

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 1

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 2

- 24.02 1

- 24.62 1

- 24.77 1

- 25.00 7

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 1

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 16

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 1

- 3.79 2

- 3.80 1

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 2

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.39 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 39.12 1

- 39.68 1

- 395.81 1

- 4.00 8

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.53 1

- 430.00 1

- 44.45 1

- 45.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 494.00 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.22 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 2

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 6

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.86 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 11

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 3

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 13

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 982.33 1

- 99.64 1

- 999.00 2

Prop 65 Chemical

Prop 65 Warning Copy

Warranty

Weight (lbs.)

3.98, 7.44, 85.00, 8.33, 0.47, 1.50, 0.36, 4.27, 8.78, 2.87, 3.47 - 681.00

19 items

- Gross Weight (lbs.) = 0.36

- Gross Weight (lbs.) = 0.47

- Gross Weight (lbs.) = 1.50

- Gross Weight (lbs.) = 2.87

- Gross Weight (lbs.) = 3.47

- Gross Weight (lbs.) = 3.98

- Gross Weight (lbs.) = 4.27

- Gross Weight (lbs.) = 681.00

- Gross Weight (lbs.) = 7.44

- Gross Weight (lbs.) = 8.33

- Gross Weight (lbs.) = 8.78

- Gross Weight (lbs.) = 85.00

- remove all filters

7/16 in.-14 1-9/16 in. 3-9/16 in. Galvanized Square U-Bolt Kits

86220

Available in both Zinc-plated and Galvanized options, Tie Down's U-Bolts Kits offer exceptional corrosion resistance, ensuring your trailer remains in top-notch condition. The Zinc-plated U-Bolts come with flat washers and nyloc nuts, providing a secure fit while preventing rusting. On the other hand, the Hot Dip Galvanized coating offers added protection against rust buildup, and the kit includes flat washers, lock washers, and nuts for easy installation. Choose from various rod widths of 7/16 in., ? in., and ½ in., paired with 14, 16, and 13 threads per inch, respectively, ensuring a perfect fit for your specific trailer needs. Whether you need individual U-Bolts or pairs, Tie Down's U-Bolts Kits have got you covered. Select between square or round shape options for seamless integration into your trailer setup.

- USD

Maxilator Bale Cracker John Deere Mount

MBC-JD5

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

Maxilator Bale Cracker Skid Steer

MBC-SS

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer mounting, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

Maxilator Bale Cracker, No Mount

MBC-NM

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

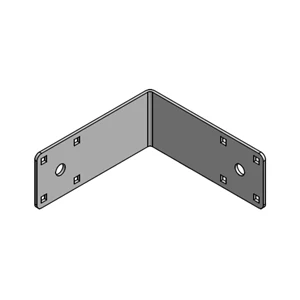

12-1/4 in. x 5 in. Commercial Grade OUTSIDE CORNER END

26428

The Commercial Grade Outside Corner End is specifically designed to provide a secure and reliable fastening solution for the ends of cross supports and docks. It ensures a stable connection and enhances the overall integrity of your marine structures. Acting in conjunction with the inside corner, the Outside Corner End is suitable for various marine applications. Crafted with commercial-grade standards, this Outside Corner End composed of ¼ in. steel is built to withstand the harsh conditions of marine environments. Its durable construction ensures long-lasting performance, providing you with peace of mind and reliable functionality.

- USD

10 in. x 5 in. Standard Grade Outside Corner End

26523

The Standard Grade Outside Corner End is specifically designed to provide a secure and reliable fastening solution for the ends of cross supports and docks. It ensures a stable connection and enhances the overall integrity of your marine structures. Acting in conjunction with the inside corner, the Outside Corner End is suitable for various marine applications. Crafted with standard-grade standards, this Outside Corner End composed of 5/32 in. steel is built to withstand the harsh conditions of marine environments. Its durable construction ensures long-lasting performance, providing you with peace of mind and reliable functionality.

- USD

1-1/2 in. x 5 in. Commercial Grade Washer Plate

26409

Elevate the strength and stability of your construction projects by utilizing two washer plates with each angle. This strategic approach ensures robust support and enhances the overall integrity of your structures. With the 1-1/2 in. x 5 in. dimensions of our washer plates, you can count on a secure and reliable connection between angles. The ample size provides ample surface area for enhanced grip and load-bearing capacity. Enjoy peace of mind knowing that your angles are reinforced with the use of two washer plates. This additional layer of support adds a level of confidence in the longevity and structural integrity of your projects.

- USD

Metal Step Fender Brackets for 14 in. to 15 in. metal fenders

44135

Tie Down's Step Fender Brackets are galvanized metal brackets that accommodate 14”-15” metal fenders, providing a secure and reliable mounting option. Designed for compatibility with 14”-15” metal fenders, these brackets ensure a perfect fit for tires. With their galvanized construction, these brackets are built to withstand the harsh marine environment, offering exceptional durability and corrosion resistance. They provide a sturdy and reliable attachment point for your fenders, ensuring they stay securely in place during transportation and while moored.

- USD

EZ Ladder Stabilizer, 1-pack

13834

Tie Down's Ladder Standoff is compatible with over 90% of aluminum ladders, ensuring that it can be easily integrated into various ladder models commonly used by professionals. Perfect for working around obstacles like windows, the standoff bracket weighs only 1.5 lbs. Each part is made of ultra-lightweight aluminum with foam resting points to protect the surface it's being placed against. Once inserted into your ladder, they extend a full foot beyond the edge of your ladder. The installation process is easy and no fasteners are required. To attach, simply press 2 bracket ends inward, toward each other, slide ends into rung holes until the proper depth is reached, and release.

- USD