close

Categories

Filter By

Brand

# of users

Country of Origin

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.21 1

- 0.22 2

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 11

- 0.51 1

- 0.52 5

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 4

- 0.60 5

- 0.63 1

- 0.64 1

- 0.65 3

- 0.67 3

- 0.68 1

- 0.70 1

- 0.71 3

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 1

- 0.93 1

- 0.94 2

- 0.95 1

- 0.96 1

- 0.97 1

- 0.98 1

- 1.00 21

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 3

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 1

- 1.62 3

- 1.63 1

- 1.64 1

- 1.67 2

- 1.68 1

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 10.60 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 2

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.20 1

- 14.43 1

- 14.54 1

- 14.64 1

- 140.00 2

- 15.00 4

- 15.14 1

- 15.15 1

- 15.50 1

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 1

- 16.05 1

- 16.33 1

- 16.80 1

- 160.00 1

- 17.00 1

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 18.00 7

- 18.08 1

- 18.24 1

- 18.30 1

- 18.46 2

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 22

- 2.02 1

- 2.05 2

- 2.09 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.47 1

- 2.50 9

- 2.53 1

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 5

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 2

- 20.02 2

- 20.27 1

- 20.34 2

- 20.68 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 2

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 1

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 1

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 1

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 2

- 24.02 1

- 24.62 1

- 24.77 1

- 25.00 7

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 1

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 16

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 1

- 3.79 2

- 3.80 1

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 2

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.39 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 39.12 1

- 39.68 1

- 395.81 1

- 4.00 8

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.53 1

- 430.00 1

- 44.45 1

- 45.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.22 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 2

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 6

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.86 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 11

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 3

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 13

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 982.33 1

- 99.64 1

- 999.00 2

Prop 65 Chemical

Prop 65 Warning Copy

- WARNING: This product can expose you to chemicals including 1,3-Butadiene, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 2

- WARNING: This product can expose you to chemicals including Di(2-ethylhexyl)phthalate (DEHP), which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 1

- WARNING: This product can expose you to chemicals including Nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 4

Warranty

2.05, 1.75, 1.92, 1.63 - 1.25

11 items

3 in. x 3 in. x 5 in. Commercial Grade Heavy Duty Angle Brackets

26398

Designed to provide exceptional support for cross structures, Tie Down’s Angle Brackets can be easily installed on the outside corners of your dock. While hardware is not included for these commercial grade ¼ inch steel brackets, their robust construction ensures unmatched strength, durability, and longevity, making them the ideal choice for demanding applications. These brackets are engineered to withstand heavy loads and provide long-lasting support, ensuring the stability and integrity of your structure.

- USD

MOUNT WINCH/BOW ROLLER

43666

- USD

4 in. Rubber Keel Roller - Spool 1/2 in. Shaft

86479

Tie Down's Keel Roller is a versatile and essential component for your boat trailer. Available in spool and center-guided variations, the choice depends on the desired look and functionality of your trailer. Tie Down's Keel Roller serves as a replacement part for any warped or distorted rollers. The primary function of the keel roller is to center and guide the keel of your boat onto the trailer during loading and unloading. By providing a smooth and controlled surface, it helps prevent the boat from shifting side to side and ensures proper alignment, simplifying the launching and retrieval process. Using multiple keel rollers at once offers even greater benefits. With several rollers strategically positioned along the trailer's cross members or axles, you can distribute the load and support the boat more effectively. This helps prevent the boat from cross members or axle contact, minimizing potential damage and wear. Constructed with durability in mind, the keel roller is designed to withstand abrasion and resist salt corrosion, making it suitable for both freshwater and saltwater environments. This ensures long-lasting performance and reliable functionality, even in harsh marine conditions.

- USD

1/2 in.-13 3-1/16 in. 6-5/16 in. Zinc Plated Square U-Bolt Kits

86330

Available in both Zinc-plated and Galvanized options, Tie Down's U-Bolts Kits offer exceptional corrosion resistance, ensuring your trailer remains in top-notch condition. The Zinc-plated U-Bolts come with flat washers and nyloc nuts, providing a secure fit while preventing rusting. On the other hand, the Hot Dip Galvanized coating offers added protection against rust buildup, and the kit includes flat washers, lock washers, and nuts for easy installation. Choose from various rod widths of 7/16 in., ? in., and ½ in., paired with 14, 16, and 13 threads per inch, respectively, ensuring a perfect fit for your specific trailer needs. Whether you need individual U-Bolts or pairs, Tie Down's U-Bolts Kits have got you covered. Select between square or round shape options for seamless integration into your trailer setup.

- USD

3 in. Rubber Bow Roller 1/2 in. Shaft

86487

Designed to prevent your boat from scraping against bolts or the roller bracket, Tie Down's Bow Rollers provide superior boat protection by minimizing potential damage and preserving the integrity of your boat's hull. In addition to protecting your boat, these bow rollers also assist in aligning your boat on the trailer. With their specialized design, they help center the boat, preventing bow-to-bow stand contact and ensuring proper alignment during loading and unloading. This feature not only makes the process easier but also helps maintain the balance and stability of your boat on the trailer. Built to support the weight of the boat on the trailer, they are engineered to withstand the load and absorb road shock, providing a secure and stable transportation experience. This ensures that your boat remains secure and protected during transit, even on rough roads or uneven terrain. One of the key advantages of these bow rollers is their cushioned stop function. Acting as a buffer for the boat's bow, they provide a soft and cushioned surface that reduces impact and minimizes the risk of damage to both the boat and the trailer. This feature adds an extra layer of protection and peace of mind during transportation.

- USD

4 in. Black Hull Sav'r PVC V-Bow Stop with 1/2 in. Shaft

86421

Tie Down's V-Bow Stop is designed to securely catch the front of your boat, providing a reliable bumper and stopping point during loading and unloading. Unlike a bow roller, the V-Bow Stop does not roll but acts as a stationary catch for the boat's bow. Its purpose is to guide the boat into position and bring it to a controlled stop, ensuring a smooth and secure loading experience. The effectiveness of the V-Bow Stop depends on the specific boat and trailer setup, making it a versatile solution for various boat types and trailers.

- USD

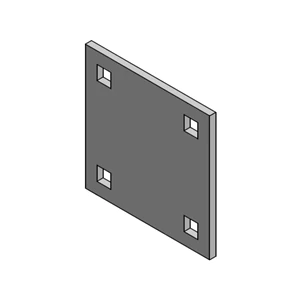

Commercial Grade Backup Plate .562 in. Square Holes 3.5 in.

26413

Tie Down's commercial-grade backup plate is designed to enhance the stability and strength of your docking system. It is specifically crafted for single T males and females, providing reliable reinforcement. These 5-inch by 5-inch plates offer robust reinforcement, adding strength and durability to your docking setup. Our backup plates promote a secure and stable docking experience by reinforcing the connection between single T males and females. They provide peace of mind, knowing that your docking system is reinforced for reliable performance. Installing the backup plates is a straightforward process. Simply attach them to the single T males and females to enhance the stability of your docking system. Tie Down's backup plates are suitable for various docking applications. Whether you're using them for residential or commercial purposes, they offer reliable reinforcement and contribute to the overall stability of your docking system.

- USD

ANGLE FRAME BRACKET

59009

Crafted from high-quality steel, Tie Down's Angle Frame Bracket serves as a pivotal connection point, ensuring a robust foundation for your structures. Designed for the attachment of longitudinal anchors to I-beams at both ends of the home, the Angle Frame Bracket is a fundamental component for anchoring security. With a 1-year warranty, Tie Down's commitment to quality is evident in the durable construction of the Angle Frame Bracket. Prioritize safety and stability by strategically determining anchor and stabilizer plate locations, along with bracket placement on the I-beam. Ensuring a strap angle of 60 degrees or lower optimizes the effectiveness of your anchoring solution. The installation process is straightforward: Drill a ½-inch hole centered in the I-beam, at least 4 inches from the edge. For wind zones II and III, connect two frame brackets with a ½-inch grade 5 bolt and nut; for wind zone I, one frame bracket is sufficient. Attach the swivel connector and strap to the angle frame brackets using ½-inch grade 5 bolts and nuts, then tighten securely.

- USD

Anchor Adapter Head

59205

Tie Down's Anchor Adapter Head, available both with the Electric Drive Machine (EDM-20) and as a standalone replacement, simplifies anchor installations. Intended for all ground anchors, this component seamlessly attaches to the motor's shaft, ensuring a secure and straightforward setup process. Crafted from high-quality steel, the adapter head guarantees durability and reliability. Its purpose is to firmly hold the anchor head, allowing for secure placement before burying the anchor in the ground. For added convenience during installation, you can utilize a ½-inch pin or slotted bolt through the adapter head and anchor head, preventing any separation from the EDM. This feature, often referred to as the safety pin hole, enhances the overall ease and safety of the installation process.

- USD