close

Categories

Filter By

Brand

Country of Origin

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.21 1

- 0.22 2

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 13

- 0.51 1

- 0.52 5

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 4

- 0.60 6

- 0.63 1

- 0.64 1

- 0.65 4

- 0.67 4

- 0.68 1

- 0.70 1

- 0.71 3

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 2

- 0.93 1

- 0.94 2

- 0.95 1

- 0.96 1

- 0.97 1

- 0.98 1

- 1.00 21

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.33 1

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 4

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 2

- 1.62 4

- 1.63 1

- 1.64 1

- 1.67 3

- 1.68 1

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.88 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 1.95 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 10.60 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 2

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.10 1

- 14.20 1

- 14.43 1

- 14.50 1

- 14.54 1

- 14.64 1

- 140.00 2

- 15.00 10

- 15.14 1

- 15.15 1

- 15.50 2

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 2

- 16.05 1

- 16.33 1

- 16.60 1

- 16.80 1

- 160.00 1

- 17.00 2

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 18.00 7

- 18.08 1

- 18.20 1

- 18.24 1

- 18.30 1

- 18.46 2

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 23

- 2.02 1

- 2.05 2

- 2.09 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.47 1

- 2.50 9

- 2.53 2

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 5

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 2

- 20.02 2

- 20.27 1

- 20.34 2

- 20.50 1

- 20.68 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 2

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 2

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 2

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 2

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 3

- 24.02 1

- 24.62 1

- 24.77 1

- 25.00 7

- 25.50 1

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 2

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 17

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 2

- 3.79 2

- 3.80 2

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 3

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.00 1

- 32.39 1

- 32.50 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 38.90 1

- 39.12 1

- 39.50 1

- 39.68 1

- 395.81 1

- 4.00 9

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.00 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.50 1

- 42.53 1

- 430.00 1

- 44.45 1

- 45.00 1

- 4500.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.22 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 2

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.27 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 7

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.86 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 12

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 4

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 14

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 982.33 1

- 989.00 1

- 99.64 1

- 999.00 2

Height (in.)

Length (in.)

Prop 65 Chemical

Prop 65 Warning Copy

- WARNING: This product can expose you to chemicals including Di(2-ethylhexyl)phthalate (DEHP), which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 2

- WARNING: This product can expose you to chemicals including Nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 11

Warranty

Weight (lbs.)

14.50, 0.68, 223.39, 2.20, 1.10, 18.00, 0.09, 7.62, 1.67, 1.75, 36.87, 20.68, 0.93 - 681.00

28 items

- Gross Weight (lbs.) = 0.09

- Gross Weight (lbs.) = 0.68

- Gross Weight (lbs.) = 0.93

- Gross Weight (lbs.) = 1.10

- Gross Weight (lbs.) = 1.67

- Gross Weight (lbs.) = 1.75

- Gross Weight (lbs.) = 14.50

- Gross Weight (lbs.) = 18.00

- Gross Weight (lbs.) = 2.20

- Gross Weight (lbs.) = 20.68

- Gross Weight (lbs.) = 223.39

- Gross Weight (lbs.) = 36.87

- Gross Weight (lbs.) = 681.00

- Gross Weight (lbs.) = 7.62

- remove all filters

Maxilator Bale Cracker John Deere Mount

MBC-JD5

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

Maxilator Bale Cracker Skid Steer

MBC-SS

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer mounting, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

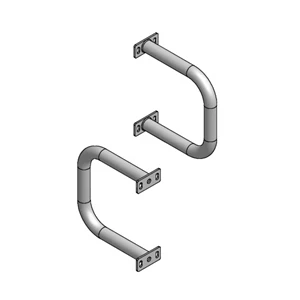

3ph Hay Spear Assembly Kit

MHS-3PH

- USD

Maxilator Bale Cracker, No Mount

MBC-NM

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

18 in. Swivel Cap Commercial Roof Anchor with 16 in. Base

70870-S16

Tie Down Safety’s Commercial Roof Anchors (CRA) stand by the Made in the USA standards of Tie Down. We manufacture anchors compatible with wood, metal, and concrete substrates with a wide variety of options. The anchorage post functions by extending through the roof, accessible during and after construction. Attach our pass-through horizontal lifeline parts for a continual hands-free fall arrest system used for perimeter work. In most cases, our commercial roof anchors can be used in window washing tieback applications. The Tie Down Commercial Roof Anchor series includes durable, galvanized steel conforming to ASTM standards. These roof anchors fit nearly all fall protection applications, and the riser height ranges from 8” to 36.” Tie Down Safety keeps exacting standards and quality control through quality raw materials and components made in the USA.

- USD

Commerical Grade Hot-Dip Galv Heavy Duty Piling Hoop

26412

Tie Down's commercial-grade piling hoop is specifically designed to provide exceptional support for pilings up to 12 inches in diameter. Crafted with a 1-1/2 inch pipe and hot dip galvanized, this piling hoop offers superior corrosion resistance. It is built to withstand the harsh conditions of marine environments, ensuring its durability and longevity. Installing the piling hoop is a hassle-free process. You can bolt it directly to the dock for a secure attachment. Alternatively, you can use the optional Deck Plate for a versatile and customizable installation, catering to your specific needs and requirements. This piling hoop is suitable for various marine applications, including docks, piers, and other structures. It provides a reliable and sturdy support system for pilings, ensuring stability and structural integrity.

- USD

3 in. x 3 in. x 5 in. Commercial Grade Heavy Duty Angle Brackets

26398

Designed to provide exceptional support for cross structures, Tie Down’s Angle Brackets can be easily installed on the outside corners of your dock. While hardware is not included for these commercial grade ¼ inch steel brackets, their robust construction ensures unmatched strength, durability, and longevity, making them the ideal choice for demanding applications. These brackets are engineered to withstand heavy loads and provide long-lasting support, ensuring the stability and integrity of your structure.

- USD

ANGLE FRAME BRACKET

59009

Crafted from high-quality steel, Tie Down's Angle Frame Bracket serves as a pivotal connection point, ensuring a robust foundation for your structures. Designed for the attachment of longitudinal anchors to I-beams at both ends of the home, the Angle Frame Bracket is a fundamental component for anchoring security. With a 1-year warranty, Tie Down's commitment to quality is evident in the durable construction of the Angle Frame Bracket. Prioritize safety and stability by strategically determining anchor and stabilizer plate locations, along with bracket placement on the I-beam. Ensuring a strap angle of 60 degrees or lower optimizes the effectiveness of your anchoring solution. The installation process is straightforward: Drill a ½-inch hole centered in the I-beam, at least 4 inches from the edge. For wind zones II and III, connect two frame brackets with a ½-inch grade 5 bolt and nut; for wind zone I, one frame bracket is sufficient. Attach the swivel connector and strap to the angle frame brackets using ½-inch grade 5 bolts and nuts, then tighten securely.

- USD

8 Bolt Gator Clamp for Zone III and Florida

59011

Engineered for precision and stability, Tie Down's Gator Beam Clamps are a vital component for secure longitudinal strap attachment. These clamps are designed to fasten to the bottom of the main beam, offering a dependable connection point for straps on each end of the home. With a focused purpose, Gator Beam Clamps are key to facilitating the attachment of straps to the I-beam, ensuring the robust anchoring of your structure. You can achieve optimal results by determining the strategic locations for anchor and stabilizer plates as well as bracket placement on the I-beam. This meticulous planning ensures a strap angle of 45 degrees or lower for maximum effectiveness. Installing the Gator Beam Clamp is straightforward and hassle-free. Employ ½-in. grade 5 bolts and nuts to affix the clamp to the I-beam. To complete the connection, use a ½-in. grade 5 bolt and nut to attach the swivel connector and strap to the bolt closest to the anchor. Tailoring to your specific needs, these clamps cater to different wind zones. Utilize 4 bolts for wind zones 1 and 2 while opting for 8 bolts in zones 3 and Florida, ensuring steadfast stability regardless of the environment.

- USD