close

Categories

Filter By

Brand

Compliance

Country of Origin

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.21 1

- 0.22 2

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 13

- 0.51 1

- 0.52 5

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 4

- 0.60 6

- 0.63 1

- 0.64 1

- 0.65 4

- 0.67 4

- 0.68 1

- 0.70 1

- 0.71 3

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 2

- 0.93 1

- 0.94 2

- 0.95 1

- 0.96 1

- 0.97 1

- 0.98 1

- 1.00 21

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.33 1

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 4

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 2

- 1.62 4

- 1.63 1

- 1.64 1

- 1.67 3

- 1.68 1

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.88 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 1.95 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 10.60 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 2

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.10 1

- 14.20 1

- 14.43 1

- 14.50 1

- 14.54 1

- 14.64 1

- 140.00 2

- 15.00 10

- 15.14 1

- 15.15 1

- 15.50 2

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 2

- 16.05 1

- 16.33 1

- 16.60 1

- 16.80 1

- 160.00 1

- 17.00 2

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 18.00 7

- 18.08 1

- 18.20 1

- 18.24 1

- 18.30 1

- 18.46 2

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 23

- 2.02 1

- 2.05 2

- 2.09 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.47 1

- 2.50 9

- 2.53 2

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 5

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 2

- 20.02 2

- 20.27 1

- 20.34 2

- 20.50 1

- 20.68 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 2

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 2

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 2

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 2

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 3

- 24.02 1

- 24.62 1

- 24.77 1

- 25.00 7

- 25.50 1

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 2

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 17

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 2

- 3.79 2

- 3.80 2

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 3

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.00 1

- 32.39 1

- 32.50 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 38.90 1

- 39.12 1

- 39.50 1

- 39.68 1

- 395.81 1

- 4.00 9

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.00 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.50 1

- 42.53 1

- 430.00 1

- 44.45 1

- 45.00 1

- 4500.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.22 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 2

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.27 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 7

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.86 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 12

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 4

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 14

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 982.33 1

- 989.00 1

- 99.64 1

- 999.00 2

Prop 65 Chemical

Prop 65 Warning Copy

- WARNING: This product can expose you to chemicals including Di(2-ethylhexyl)phthalate (DEHP), which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 2

- WARNING: This product can expose you to chemicals including Nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 6

Warranty

Weight (lbs.)

1.85, 0.40, 5.61, 15.80, 58.00, 1.67, 87.50, 1.01, 5.58, 6.16, 11.84 - 5.94

18 items

- Gross Weight (lbs.) = 0.40

- Gross Weight (lbs.) = 1.01

- Gross Weight (lbs.) = 1.67

- Gross Weight (lbs.) = 1.85

- Gross Weight (lbs.) = 11.84

- Gross Weight (lbs.) = 15.80

- Gross Weight (lbs.) = 5.58

- Gross Weight (lbs.) = 5.61

- Gross Weight (lbs.) = 5.94

- Gross Weight (lbs.) = 58.00

- Gross Weight (lbs.) = 6.16

- Gross Weight (lbs.) = 87.50

- remove all filters

Yellow Universal Compression Clamp (UCC) Guardrail Base

71091

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

Galvanized Universal Compression Clamp (UCC) Guardrail Base

71091G

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

STAND 5400-8400LB BOW

43585

- USD

FNDR SGL RR 7X25.75X10.62 CR 16G NH

44913

- USD

FNDR SGL JRRK 10X36X19 CR 16G NH

44925

- USD

10 Gauge Zinc-Plated Swivel Strap Connector, Connector Only

59336

Designed for attachment of uplift straps at the factory OEM or in the field, Tie Down's Swivel "L" Tie Plate Assembly offers versatile solutions for enhanced structural integrity. The "L" Plate configuration optimizes uplift support by attaching securely to the floor and angling down alongside the rim joist, providing robust uplift reinforcement. Customize your assembly with the option to order a heavier finish coating, ensuring durability that matches your specific requirements. The "L" Tie Plate itself is crafted from 14-gauge pre-galvanized steel, ensuring enduring performance. The swivel strap connector, available separately, is built from 10-gauge zinc, offering steadfast support. Whether bolting the swivel to the tie strap or crimping the strap through the swivel connector, the installation process adapts to your preferences, guaranteeing a secure connection. Affix the assembly with confidence using either 0.131 x 1-1/2” nails or #8 x 1-1/2” screws, engaging at least 50% of the nine pre-punched holes in the strap, guaranteeing a secure and reliable hold. Tailor your solution with the choice of a comprehensive kit, a separate swivel strap connector, or the "L" Tie Plate only, ensuring flexibility to match your unique needs. The kit option includes essential components for a hassle-free installation, such as the connector, “L” Tie Plate, bolt, two washers, and a Nyloc nut, offering a comprehensive uplift support solution. Rest easy knowing that the Swivel "L" Tie Plate Assembly is backed by a 1-year warranty, underlining its quality and dependability.

- USD

3 in. x 16 in. Galvanized Tie Plate

59341

This tie plate, composed of 14 gauge, pre-galvanized, zinc-plated steel, ensures utmost durability and reliability with an impressive 2,400 lbs. capacity. Measuring 3 in. x 16 in., this stabilizer promises utmost stability in every manufactured home project.

- USD

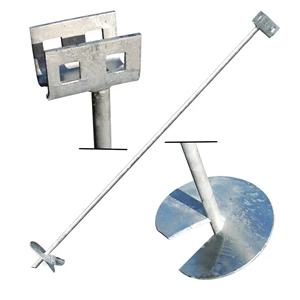

IRON ROOT DOUBLE HEAD MANUFACTURED HOME EARTH ANCHORS A Model MI2H5/8 with 5/8 in. rod, 48 in. long, 6 in. helix, Class 4A

59081

Tie Down's Iron Root Double Head Manufactured Home Earth Anchors are expertly designed to deliver exceptional anchoring performance, specifically tailored for uplift and frame tie applications. Featuring a double-headed configuration, these anchors ensure robust attachment for both sidewall and I-beam connections. This innovative design opens doors to a variety of strapping and attachment options, including slotted bolts. The double-headed nature of these anchors facilitates the use of two bolts, enhancing their structural integrity. The plates are positioned in front of the Iron Root anchors, making them ideal for frame attachment in wind zones 2 and 3, providing reliable security against lateral forces. This design offers remarkable versatility across different wind zones, offering the necessary adaptability to varying conditions. With a 6 in. or 7 in. helix, these anchors are engineered to provide optimal grip and stability in the soil. They are specifically engineered for use within soil classes 4A and 4B, ensuring a dependable anchoring solution for various ground conditions.

- USD

8 ft. Frame Tie with Buckle, 50 per box

59146

Tie Down's Frame Tie with Buckle includes a galvanized strap pre-attached with a durable buckle, ensuring a secure and hassle-free connection to the frame. The process is straightforward: effortlessly push the strap's end between the inside of the frame "I" beam and the floor. Position the buckle at the upper end of the "I" beam frame, then wrap the strap around the beam and thread its end through the slot in the buckle. A simple pull secures the strap, keeping the buckle in place for added stability. Choose the perfect length for your project with options ranging from 7 to 16 ft. Available in convenient quantities, you can opt for boxes containing 30 or 50 kits or bundles of 8 kits each. With Tie Down's Frame Tie with Buckle, you're equipped with a smart solution that streamlines installation, saving you time and effort while ensuring a dependable connection to the frame.

- USD