close

Filter By

Brand

# users on fall arrest

# users on fall restraint

Color

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.21 1

- 0.22 2

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 11

- 0.51 1

- 0.52 5

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 4

- 0.60 5

- 0.63 1

- 0.64 1

- 0.65 3

- 0.67 3

- 0.68 1

- 0.70 1

- 0.71 3

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 1

- 0.93 1

- 0.94 2

- 0.95 1

- 0.96 1

- 0.97 1

- 0.98 1

- 1.00 21

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 3

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 1

- 1.62 3

- 1.63 1

- 1.64 1

- 1.67 2

- 1.68 1

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 10.60 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 2

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.20 1

- 14.43 1

- 14.54 1

- 14.64 1

- 140.00 2

- 15.00 4

- 15.14 1

- 15.15 1

- 15.50 1

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 1

- 16.05 1

- 16.33 1

- 16.80 1

- 160.00 1

- 17.00 1

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 18.00 7

- 18.08 1

- 18.24 1

- 18.30 1

- 18.46 2

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 21

- 2.02 1

- 2.05 2

- 2.09 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.47 1

- 2.50 9

- 2.53 1

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 5

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 2

- 20.02 2

- 20.27 1

- 20.34 2

- 20.68 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 2

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 1

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 2

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 1

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 2

- 24.02 1

- 24.62 1

- 24.77 1

- 25.00 7

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 1

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 16

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 1

- 3.79 2

- 3.80 1

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 2

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.39 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 39.12 1

- 39.68 1

- 395.81 1

- 4.00 8

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.53 1

- 430.00 1

- 44.45 1

- 45.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.22 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 2

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 6

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.86 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 11

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 3

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 13

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 982.33 1

- 99.64 1

- 999.00 2

Height (in.)

Length (in.)

Prop 65 Chemical

Prop 65 Warning Copy

- WARNING: This product can expose you to chemicals including Di(2-ethylhexyl)phthalate (DEHP), which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 3

- WARNING: This product can expose you to chemicals including Nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 12

Warranty

Weight (lbs.)

1.75, 5.64, 1.74, 2.98, 0.84, 0.89, 1.72, 1.30, 10.00, 7.44, 6.72, 20.34, 55.70, 1.27 - 3.98

33 items

- Gross Weight (lbs.) = 0.84

- Gross Weight (lbs.) = 0.89

- Gross Weight (lbs.) = 1.27

- Gross Weight (lbs.) = 1.30

- Gross Weight (lbs.) = 1.72

- Gross Weight (lbs.) = 1.74

- Gross Weight (lbs.) = 1.75

- Gross Weight (lbs.) = 10.00

- Gross Weight (lbs.) = 2.98

- Gross Weight (lbs.) = 20.34

- Gross Weight (lbs.) = 3.98

- Gross Weight (lbs.) = 5.64

- Gross Weight (lbs.) = 55.70

- Gross Weight (lbs.) = 6.72

- Gross Weight (lbs.) = 7.44

- remove all filters

2 FT BUNK BOARD GUIDE ON KIT

86470

- USD

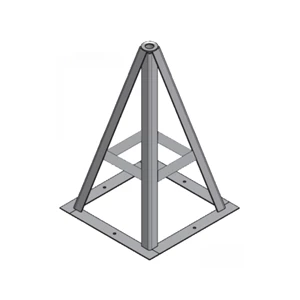

24 in. Steel Braced Support Piers, 6000 lb. Capacity

MPP24

A reliable and efficient alternative to traditional dry-stacked blocks, our Steel Support Piers are designed and engineered to handle vertical loads with ease, providing a support rating of up to 6,000 lbs. These Support Piers are versatile in application, suitable for a wide range of factory-built structures including manufactured homes, mobile commercial units, classrooms, multiplexes, sheds, and similar structures. With the ability to withstand various wind zone conditions, except for “Exposure D” or areas within 1,500 ft. of the coastline, our Steel Support Piers are designed to provide exceptional stability and support. Available up to a maximum of 30 in. and in braced support as well, these Support Piers are compatible with a variety of heads to prevent movement after attachment to the beam or marriage line.

- USD

4-Way Roof Anchor Plate for 1 Worker in Fall Arrest and 2 Workers in Fall Restraint | 4 Connection Points

65080

The 4-Way Roof Anchor by Tie Down Engineering provides an anchor plate that offers a fall protection anchor point for one worker in fall arrest or two workers in fall restraint. The multidirectional 4-Way Roof Anchor resulted from collaboration between roofing contractors who require the ability to move in multiple directions while using a single tie-off point. The four connection points increase the worker’s range of motion, allowing the worker to detach from one connection point to the next. This anchor plate works for both fall arrest and fall restraint. This product’s design makes it compatible with metal, wood, and concrete applications. A horizontal lifeline system works due to the 90° angles between each anchor point on the anchor plate. Tie Down maintains high standards and quality control through quality raw materials and components made in the USA.

- USD

Galvanized Socket Guardrail Base Assembly

71094G

Tie Down's Socket Guardrail Base stands out as the lightest guardrail base in the United States, weighing just 58 lbs. Its innovative design includes base plates that nest and stack efficiently, simplifying transportation and storage. Featuring convenient toe board slots and handle holes, this base reduces the risk of soft tissue injuries during handling on the job site. It comes with the option of a galvanized finish for enhanced durability and resistance. Suitable for both permanent and temporary applications, it meets OSHA 1926.502 and 1910 Subpart D standards, all without penetrating the roof substrate. The coating ensures extreme longevity while its installation time is slashed by over 30%, requiring no drilling or tools. This versatile base fits seamlessly between standing seams and is tested to withstand Category 5 hurricane wind forces. Added benefits include a protective rubber footing, economical shipment costs, and multi-directional adaptability for all your safety needs.

- USD

4 ft. TranzPorter Track Sections

10092

With a height of 4 feet, the TranzPorter Track Sections by Tie Down offer excellent stacking capabilities, allowing for a total height of up to 44 feet when combined with the 8-foot base. Designed for versatility, the 4-foot track is compatible with the TranzPorter TP250 and TP400 models, as well as Tie Down's other hoisting ladder, the TranzVolt. Weighing only 10 lbs., the 4-foot track sections are lightweight and portable. This makes transportation and setup hassle-free, allowing for easy maneuverability on the job site. The TranzPorter Track Sections are manufactured with high standards and undergo rigorous quality controls. Utilizing top-notch raw materials and component parts made in the USA, these track sections ensure reliable performance and durability.

- USD

2 x 2 x 42 in. 11 Gauge Bow Stand

43604

- USD

3 in. x 3 in. x 5 in. Commercial Grade Heavy Duty Angle Brackets

26398

Designed to provide exceptional support for cross structures, Tie Down’s Angle Brackets can be easily installed on the outside corners of your dock. While hardware is not included for these commercial grade ¼ inch steel brackets, their robust construction ensures unmatched strength, durability, and longevity, making them the ideal choice for demanding applications. These brackets are engineered to withstand heavy loads and provide long-lasting support, ensuring the stability and integrity of your structure.

- USD

10 in. x 5 in. Commercial Grade Outside Corner End

26402

The Commercial Grade Outside Corner End is specifically designed to provide a secure and reliable fastening solution for the ends of cross supports and docks. It ensures a stable connection and enhances the overall integrity of your marine structures. Acting in conjunction with the inside corner, the Outside Corner End is suitable for various marine applications. Crafted with commercial-grade standards, this Outside Corner End composed of ¼ in. steel is built to withstand the harsh conditions of marine environments. Its durable construction ensures long-lasting performance, providing you with peace of mind and reliable functionality.

- USD

ANGLE FRAME BRACKET

59009

Crafted from high-quality steel, Tie Down's Angle Frame Bracket serves as a pivotal connection point, ensuring a robust foundation for your structures. Designed for the attachment of longitudinal anchors to I-beams at both ends of the home, the Angle Frame Bracket is a fundamental component for anchoring security. With a 1-year warranty, Tie Down's commitment to quality is evident in the durable construction of the Angle Frame Bracket. Prioritize safety and stability by strategically determining anchor and stabilizer plate locations, along with bracket placement on the I-beam. Ensuring a strap angle of 60 degrees or lower optimizes the effectiveness of your anchoring solution. The installation process is straightforward: Drill a ½-inch hole centered in the I-beam, at least 4 inches from the edge. For wind zones II and III, connect two frame brackets with a ½-inch grade 5 bolt and nut; for wind zone I, one frame bracket is sufficient. Attach the swivel connector and strap to the angle frame brackets using ½-inch grade 5 bolts and nuts, then tighten securely.

- USD