close

Filter By

Brand

Country of Origin

Gross Weight (lbs.)

- 0.05 1

- 0.07 2

- 0.08 1

- 0.09 2

- 0.10 2

- 0.11 1

- 0.12 1

- 0.16 1

- 0.20 1

- 0.22 1

- 0.25 1

- 0.26 2

- 0.27 1

- 0.28 3

- 0.29 2

- 0.30 4

- 0.31 1

- 0.33 2

- 0.34 5

- 0.35 27

- 0.36 1

- 0.37 1

- 0.39 1

- 0.40 3

- 0.41 2

- 0.43 1

- 0.44 1

- 0.45 3

- 0.46 2

- 0.47 4

- 0.48 5

- 0.50 13

- 0.51 1

- 0.52 4

- 0.54 2

- 0.55 2

- 0.57 46

- 0.58 1

- 0.59 3

- 0.60 6

- 0.63 1

- 0.64 1

- 0.65 4

- 0.67 3

- 0.68 1

- 0.70 1

- 0.71 2

- 0.72 1

- 0.73 2

- 0.75 4

- 0.76 1

- 0.77 2

- 0.78 3

- 0.80 2

- 0.82 1

- 0.83 1

- 0.84 3

- 0.85 2

- 0.86 3

- 0.88 2

- 0.89 1

- 0.90 2

- 0.93 1

- 0.94 2

- 0.95 1

- 0.97 1

- 0.98 1

- 1.00 25

- 1.01 1

- 1.04 1

- 1.05 1

- 1.06 1

- 1.08 1

- 1.10 1

- 1.11 1

- 1.13 2

- 1.14 1

- 1.15 1

- 1.20 3

- 1.22 3

- 1.23 2

- 1.24 1

- 1.25 3

- 1.26 1

- 1.27 1

- 1.28 1

- 1.30 3

- 1.31 1

- 1.32 2

- 1.33 1

- 1.34 3

- 1.37 1

- 1.38 2

- 1.40 6

- 1.42 3

- 1.44 1

- 1.46 1

- 1.48 2

- 1.50 4

- 1.52 1

- 1.53 1

- 1.55 4

- 1.58 3

- 1.59 1

- 1.60 2

- 1.62 4

- 1.63 1

- 1.64 1

- 1.67 3

- 1.69 1

- 1.70 6

- 1.71 1

- 1.72 1

- 1.74 2

- 1.75 3

- 1.76 1

- 1.77 1

- 1.80 5

- 1.81 1

- 1.82 1

- 1.83 1

- 1.85 1

- 1.86 1

- 1.90 2

- 1.92 2

- 1.93 2

- 1.94 1

- 1.95 1

- 10.00 9

- 10.05 1

- 10.14 1

- 10.21 1

- 10.50 1

- 100.00 2

- 103.81 3

- 1076.00 2

- 11.00 9

- 11.50 1

- 11.60 2

- 11.84 1

- 11.90 2

- 11.93 1

- 11.99 1

- 1142.00 1

- 1190.00 1

- 12.00 8

- 12.12 1

- 12.19 1

- 12.28 1

- 12.50 1

- 12.54 1

- 12.62 1

- 12.80 1

- 12.87 1

- 12.90 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 3

- 13.25 1

- 13.30 1

- 13.50 1

- 13.66 1

- 14.00 3

- 14.10 1

- 14.20 1

- 14.50 1

- 14.54 1

- 140.00 2

- 15.00 10

- 15.14 1

- 15.15 1

- 15.50 2

- 15.70 1

- 15.80 1

- 15.87 1

- 150.00 1

- 1531.31 3

- 16.00 2

- 16.33 1

- 16.60 1

- 16.80 1

- 160.00 1

- 17.00 2

- 17.25 1

- 17.35 1

- 17.41 1

- 17.44 1

- 17.50 1

- 17.80 1

- 1740.00 1

- 18.00 7

- 18.08 1

- 18.20 1

- 18.24 1

- 18.30 1

- 18.93 1

- 185.00 1

- 19.00 2

- 19.20 2

- 19.50 2

- 19.60 1

- 2.00 23

- 2.02 1

- 2.05 1

- 2.10 2

- 2.12 2

- 2.19 1

- 2.20 2

- 2.25 3

- 2.28 3

- 2.29 1

- 2.30 2

- 2.32 1

- 2.35 1

- 2.40 3

- 2.42 1

- 2.44 1

- 2.45 1

- 2.46 1

- 2.47 1

- 2.50 9

- 2.53 2

- 2.55 1

- 2.60 4

- 2.64 1

- 2.66 3

- 2.70 1

- 2.80 3

- 2.85 1

- 2.87 1

- 2.90 2

- 2.98 1

- 20.00 2

- 20.02 2

- 20.34 2

- 20.50 1

- 20.82 1

- 20.95 1

- 200.00 2

- 201.40 1

- 2069.00 2

- 21.00 5

- 21.20 1

- 21.30 1

- 21.50 1

- 21.82 1

- 22.00 2

- 22.50 1

- 22.68 1

- 22.80 1

- 220.00 2

- 221.00 1

- 221.46 2

- 223.39 1

- 225.00 2

- 23.00 2

- 23.32 1

- 23.38 1

- 23.50 2

- 23.70 1

- 230.00 1

- 2390.00 1

- 24.00 3

- 24.02 1

- 25.00 7

- 25.50 1

- 26.88 1

- 27.00 1

- 27.30 1

- 27.56 1

- 27.75 2

- 275.00 1

- 28.00 2

- 28.88 1

- 29.00 2

- 29.75 1

- 3.00 6

- 3.02 1

- 3.07 1

- 3.08 3

- 3.10 1

- 3.12 3

- 3.14 1

- 3.15 1

- 3.20 2

- 3.25 1

- 3.35 1

- 3.37 1

- 3.42 1

- 3.44 1

- 3.47 1

- 3.48 1

- 3.50 17

- 3.54 1

- 3.55 1

- 3.56 1

- 3.59 2

- 3.64 2

- 3.69 1

- 3.73 1

- 3.75 2

- 3.79 2

- 3.80 2

- 3.82 1

- 3.85 1

- 3.88 1

- 3.89 1

- 3.98 1

- 30.00 3

- 30.64 2

- 300.00 5

- 31.08 1

- 31.30 1

- 31.53 1

- 315.14 3

- 32.00 1

- 32.39 1

- 32.50 1

- 32.93 2

- 325.00 1

- 33.00 3

- 33.28 1

- 349.74 1

- 35.00 2

- 35.20 1

- 350.00 3

- 36.00 2

- 36.87 1

- 37.00 4

- 37.36 2

- 37.42 1

- 37.50 1

- 38.00 1

- 39.12 1

- 39.50 1

- 395.81 1

- 4.00 9

- 4.10 1

- 4.11 1

- 4.14 1

- 4.15 2

- 4.24 3

- 4.25 1

- 4.27 1

- 4.30 1

- 4.42 1

- 4.44 2

- 4.48 1

- 4.50 7

- 4.60 1

- 4.73 1

- 4.76 1

- 4.80 1

- 4.81 1

- 4.98 1

- 40.00 1

- 40.32 1

- 40.53 1

- 41.00 1

- 41.50 2

- 41.80 2

- 42.00 2

- 42.50 1

- 430.00 1

- 44.45 1

- 45.00 2

- 4500.00 1

- 46.41 1

- 48.76 1

- 49.92 1

- 5.00 11

- 5.11 1

- 5.13 2

- 5.20 1

- 5.30 3

- 5.34 2

- 5.37 1

- 5.45 1

- 5.50 1

- 5.54 1

- 5.58 1

- 5.60 1

- 5.61 1

- 5.64 2

- 5.66 1

- 5.67 1

- 5.68 1

- 5.74 1

- 5.85 1

- 5.86 1

- 5.94 1

- 50.00 2

- 51.00 1

- 51.15 1

- 517.00 1

- 52.00 1

- 53.00 1

- 55.70 2

- 56.00 2

- 58.00 2

- 6.00 11

- 6.03 1

- 6.08 1

- 6.09 1

- 6.10 1

- 6.12 1

- 6.14 1

- 6.16 2

- 6.25 1

- 6.26 1

- 6.34 1

- 6.36 1

- 6.39 1

- 6.40 2

- 6.50 10

- 6.60 4

- 6.67 1

- 6.68 1

- 6.72 1

- 6.76 1

- 6.80 2

- 6.89 1

- 6.90 1

- 60.00 2

- 61.00 1

- 61.04 1

- 630.00 1

- 65.00 1

- 681.00 3

- 7.00 8

- 7.20 2

- 7.21 1

- 7.27 1

- 7.32 1

- 7.41 1

- 7.44 1

- 7.50 7

- 7.55 1

- 7.62 1

- 7.65 1

- 7.67 1

- 7.72 1

- 7.81 1

- 7.82 1

- 7.88 1

- 7.94 2

- 7.97 1

- 70.00 2

- 703.00 1

- 74.75 1

- 750.00 1

- 79.00 1

- 8.00 12

- 8.17 1

- 8.19 1

- 8.20 1

- 8.33 1

- 8.48 2

- 8.50 4

- 8.53 1

- 8.66 1

- 8.67 1

- 8.68 1

- 8.70 1

- 8.75 1

- 8.78 1

- 8.80 1

- 8.81 1

- 8.98 1

- 825.00 1

- 85.00 1

- 850.00 2

- 87.50 1

- 9.00 14

- 9.22 1

- 9.30 1

- 9.50 2

- 9.67 1

- 90.00 2

- 902.00 1

- 94.00 1

- 95.00 1

- 989.00 1

- 99.64 1

- 999.00 2

Prop 65 Chemical

Prop 65 Warning Copy

- WARNING: This product can expose you to chemicals including 1,3-Butadiene, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 2

- WARNING: This product can expose you to chemicals including Nickel, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov 7

Warranty

1.55, 5.20, 12.28, 6.14, 12.54, 2.35, 3.56, 13.66 - 681.00

14 items

5 in. Rubber Wobble Roller - Ribbed 1.15 in. Shaft

86494

The perfect solution for boaters seeking enhanced traction and shock absorption during launching, loading, and hitching, Tie Down's Ribbed Wobble Roller’s ribbed design provides extra grip for slick hulls, ensuring a secure and stable boat-loading experience. Designed as an ideal alternative to trailer bunks, the ribbed wobble roller is particularly beneficial when launching on shallow ramps or in shallow waters. It is important to note that the roller is a replacement part and requires the trailer to come with the assembly already installed. With its ability to assist in loading the boat while preventing scratches and damage, the Tie Down Ribbed Wobble Roller is a must-have accessory for boating enthusiasts.

- USD

9 in. x 2 in. Side Guide Roller with 1/2 in. Shaft

86475

Tie Down's Slide Guide Roller is the perfect replacement part for fixed angle roller guides (86102) and adjustable roller side guides (86106). Designed to fit seamlessly on top or beneath the guide on's frame, these rollers ensure smooth and reliable boat loading and unloading experiences. Crafted with high-quality rubber, the slide guide roller is rust-resistant and built to withstand the elements for long-lasting durability.

- USD

Maxilator Bale Cracker John Deere Mount

MBC-JD5

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

Maxilator Bale Cracker Skid Steer

MBC-SS

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer mounting, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

Maxilator Bale Cracker, No Mount

MBC-NM

An efficient solution for handling net-wrapped dry hay, Maxilator’s innovative Bale Cracker simplifies the entire process, allowing a single operator to effortlessly grab the hale bale, cut the wrap, release the bale to the ground, and dispose of the wrapping the material remotely from their seat. Featuring a patented wrap retention mechanism, the machine pierces the bale's covering, and a precision knife swiftly cuts through the net and wrapping material, ensuring a clean and efficient operation. When the net is cut and securely held, one of the forks pivots away from the bale, allowing it to gently descend to the ground. Simultaneously, the wrapping material is lifted away, eliminating any risk of ingestion by your animals. This keeps the operator comfortably seated, in control, and out of harm's way. Available with Skid-Steer, Euro Global, and Deere 500, the Bale Cracker is intended to pick up, move, and unwrap bales up to 5 ft. x 6 ft. in size. Its durable plasticoat finish resists rain and provides rust prevention, ensuring durable and long-lasting equipment.

- USD

3/16 in. x 22 in. x 4 in. x 6 in. Commercial Grade DECK PLATE

26416

Our heavy-duty deck plate provides a versatile solution for attaching various components to your dock. It can be conveniently bolted from the top and side, offering flexibility in installation options to suit your specific needs. The angle is designed to seamlessly work with piling hoops, allowing for easy integration and versatility in your dock system. It can be securely bolted to the angle, enabling convenient seasonal removal of the piling hoops for added convenience. With a length of 22 in., a top width of 4 in., and a bottom width of 6 in., this angle offers optimal dimensions for effective attachment and support. It provides ample surface area for secure fastening and ensures proper load distribution, ensuring the stability of your dock. Crafted with heavy-duty materials, this angle is built to withstand the elements and endure the test of time. Its 3/16 in. thickness ensures exceptional strength and durability, ensuring reliable performance and longevity for your dock, so you can enjoy its benefits for years to come. Installing and maintaining this angle is hassle-free. Its bolt-on design allows for straightforward installation from the top and side of the dock. Additionally, its removable piling hoop feature enables easy seasonal removal, providing convenience and flexibility for your dock's upkeep.

- USD

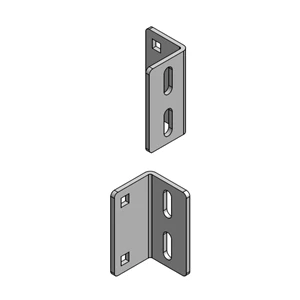

2-3/4 in. x 5 in. Commercial Grade Heavy Duty Cleat Angle

26422

Elevate the strength and stability of your dock system with our heavy-duty angles, specifically designed for reliable cross support. Trust in the durability and resilience of our commercial-grade brackets, engineered to withstand rigorous conditions and deliver long-lasting performance. With our robust angles, you can have peace of mind knowing that your dock is supported by high-quality brackets built to endure heavy-duty applications. Experience enhanced stability and structural integrity for your dock with our reliable angles, ensuring the utmost security and longevity for your docking needs.

- USD

FNDR SGL RR 7X20X5.62 CR 16G NH

44911

- USD

16 in. x 22.5 in. ABS/PLASTIC FOUNDATION PADS, 2.5 sq. ft.

59301

Designed to be placed under and support steel piers that hold up your mobile home, Tie Down's ABS Foundation Pads offer an innovative and efficient solution for your foundation needs. These pads are lighter than traditional concrete, leading to labor and cost savings during installation. With larger pad sizes, they increase spacing, saving valuable time and materials. Environmentally conscious, these foundation pads are made from recycled materials, contributing to sustainability efforts. Their stackable design allows for easy expansion, creating larger pad areas and wider pier spacing, ideal for various applications. The ABS Foundation Pads come in both single and multi-pad configurations, catering to different soil capacities. They are approved for use by HUD 3285.312(3) and are listed and labeled by RADCO #1345, ensuring compliance with industry standards.

- USD