close

Categories

Filter By

Compliance

Country of Origin

Division

Gross Weight (lbs.)

- 0.07 1

- 0.22 1

- 0.67 1

- 1.00 7

- 10.00 1

- 100.00 1

- 1076.00 2

- 11.00 3

- 1142.00 1

- 1190.00 1

- 1208.00 1

- 13.00 3

- 14.00 1

- 14.27 1

- 15.19 1

- 17.00 1

- 18.46 1

- 185.00 1

- 2.00 9

- 2.02 1

- 20.27 1

- 20.68 1

- 2069.00 1

- 21.00 2

- 2390.00 1

- 24.62 1

- 24.77 1

- 27.00 1

- 275.00 1

- 28.00 1

- 29.00 1

- 31.30 1

- 33.00 2

- 35.00 1

- 38.00 1

- 4.00 2

- 42.00 2

- 494.00 1

- 5.00 1

- 5.22 1

- 55.70 2

- 58.00 2

- 6.00 1

- 61.00 1

- 703.00 1

- 982.33 1

- 999.00 2

Warranty

58.00, 982.33, 55.70, 5.00 - GuardRail

6 items

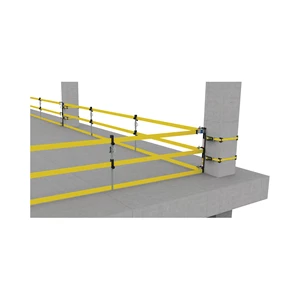

60 ft. WebRail Kit - Portable Fall Arrest & Tensioned Guardrail System

73073

Tie Down's 60 ft. WebRail represents a revolutionary advancement in fall protection due to its patented technology that offers both fall arrest and passive protection without penetrating the structure. The WebRail kit attaches to the WebRail vertical fall arrest support rather than the building column, ensuring that in the event of a fall, workers are prevented from colliding with the floor or column. With an impressive capacity for up to four users in fall arrest per single span of webbing, the top, mid, and toe webbing is rated at an impressive 20,000 lbs., exceeding OSHA 1926 and 1910 requirements. The 4 in. DOT webbing is fire retardant, UV-resistant, and chafe-resistant, ensuring durability and longevity. Versatile and accommodating, it is designed for use with both round and square columns, offering adaptability to various structures. This WebRail is an integral component of a fall protection system, compatible with lanyards or SRL vertical fall protection lifelines, providing comprehensive safety assurance on the job.

- USD

Yellow Universal Compression Clamp (UCC) Guardrail Base

71091

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

Yellow Socket Guardrail Base Assembly

71094

Tie Down's Socket Guardrail Base stands out as the lightest guardrail base in the United States, weighing just 58 lbs. Its innovative design includes base plates that nest and stack efficiently, simplifying transportation and storage. Featuring convenient toe board slots and handle holes, this base reduces the risk of soft tissue injuries during handling on the job site. It comes with the option of a galvanized finish for enhanced durability and resistance. Suitable for both permanent and temporary applications, it meets OSHA 1926.502 and 1910 Subpart D standards, all without penetrating the roof substrate. The coating ensures extreme longevity while its installation time is slashed by over 30%, requiring no drilling or tools. This versatile base fits seamlessly between standing seams and is tested to withstand Category 5 hurricane wind forces. Added benefits include a protective rubber footing, economical shipment costs, and multi-directional adaptability for all your safety needs.

- USD

Galvanized Universal Compression Clamp (UCC) Guardrail Base

71091G

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

Galvanized Socket Guardrail Base Assembly

71094G

Tie Down's Socket Guardrail Base stands out as the lightest guardrail base in the United States, weighing just 58 lbs. Its innovative design includes base plates that nest and stack efficiently, simplifying transportation and storage. Featuring convenient toe board slots and handle holes, this base reduces the risk of soft tissue injuries during handling on the job site. It comes with the option of a galvanized finish for enhanced durability and resistance. Suitable for both permanent and temporary applications, it meets OSHA 1926.502 and 1910 Subpart D standards, all without penetrating the roof substrate. The coating ensures extreme longevity while its installation time is slashed by over 30%, requiring no drilling or tools. This versatile base fits seamlessly between standing seams and is tested to withstand Category 5 hurricane wind forces. Added benefits include a protective rubber footing, economical shipment costs, and multi-directional adaptability for all your safety needs.

- USD

SkyCage Pedestrian Base Post

70812

The SkyCage System by Tie Down serves as perimeter protection or an alternative to a standard guardrail system. The SkyCage Pedestrian Base Post works with the SkyCage Pedestrian Base for pedestrian traffic control. The Post drops into the Base and the Panels secure to it. This post does not make a fall protection guardrail system unless used with the Universal Guardrail system, Gator base and an additional counter weighted system. This product works best in crowd control and traffic situations. Tie Down maintains high standards and quality controls using quality raw materials and component parts made in the USA.

- USD

1 - 6 of 6

1