close

Filter By

Brand

Compatible with

Compliance

Country of Origin

Division

Gross Weight (lbs.)

- 0.07 1

- 0.22 1

- 0.67 1

- 1.00 9

- 10.00 3

- 10.21 1

- 10.60 1

- 100.00 1

- 1076.00 2

- 11.00 5

- 11.93 1

- 1142.00 1

- 1190.00 1

- 1200.00 1

- 1208.00 1

- 1285.00 1

- 13.00 4

- 14.00 1

- 14.27 1

- 14.43 1

- 140.00 1

- 15.19 1

- 17.00 1

- 18.46 1

- 185.00 3

- 2.00 9

- 2.02 1

- 20.00 1

- 20.27 1

- 20.68 1

- 200.00 2

- 2069.00 1

- 21.00 3

- 21.50 1

- 225.00 1

- 2390.00 1

- 24.62 1

- 24.77 1

- 25.00 2

- 27.00 1

- 275.00 1

- 28.00 1

- 29.00 1

- 30.00 2

- 300.00 2

- 31.30 1

- 32.39 1

- 32.93 2

- 33.00 3

- 349.74 1

- 35.00 1

- 36.87 1

- 37.00 3

- 38.00 1

- 39.68 1

- 395.81 1

- 4.00 2

- 42.00 2

- 42.53 1

- 430.00 1

- 494.00 1

- 5.00 1

- 5.22 1

- 517.00 1

- 55.70 2

- 56.00 1

- 58.00 2

- 6.00 1

- 61.00 1

- 630.00 1

- 65.00 1

- 687.00 1

- 70.00 1

- 703.00 1

- 750.00 1

- 8.00 2

- 825.00 1

- 9.00 1

- 902.00 1

- 982.33 1

- 999.00 2

Warranty

42.53, 55.70, 275.00, 65.00, 58.00, 27.00, 10.21, 31.30 - Safety

10 items

Standing Seam Guardrail Assembly

70838

Tie Down's Standing Seam Guardrail Assembly is expertly crafted for standing seam roofs, serving as an essential component for constructing robust guardrails. The kit includes universal S-5 seam clamps, ensuring compatibility with various standing seam roof types. The base features slots that provide adjustability to fit different seam spacing, offering flexibility in installation. As part of the Zip Rail Fittings system, it acts as a foundational element for assembling reliable guardrails on elevated surfaces. Users have the option to customize their assembly by incorporating alternative Zip Rail Fittings beyond what is included in the kit, allowing for tailored configurations. The Standing Seam Guardrail Assembly includes the Standing Seam Guardrail Base (70838-1) and all necessary hardware, providing a comprehensive solution for creating secure guardrails on standing seam roofs.

- USD

Tie Down Engineering Hatch Mate | Universal Roof Access Hatch System | Roofing Hatch Safety Tools edit

73057

Tie Down’s Hatch Mate is the first roof hatch system to ensure universal mounting on either side of interior fixed ladders by requiring only six fasteners for attachment. Shipped fully assembled, its innovative design uses a chain mounted to an actuation pulley. This chain can be shortened or lengthened for roof heights up to 28 ft. Engineered for ease of use, this pulley system requires only several pulls on the chain to unlock and open the upper roof hatch and several pulls on the opposite side of the chain to close the hatch. To ensure permanent closure, the operator only needs to place the chain into the lock mounting bracket and lock with a standard lock and key.

- USD

Galvanized Universal Compression Clamp (UCC) Guardrail Base

71091G

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

Galvanized Socket Guardrail Base Assembly

71094G

Tie Down's Socket Guardrail Base stands out as the lightest guardrail base in the United States, weighing just 58 lbs. Its innovative design includes base plates that nest and stack efficiently, simplifying transportation and storage. Featuring convenient toe board slots and handle holes, this base reduces the risk of soft tissue injuries during handling on the job site. It comes with the option of a galvanized finish for enhanced durability and resistance. Suitable for both permanent and temporary applications, it meets OSHA 1926.502 and 1910 Subpart D standards, all without penetrating the roof substrate. The coating ensures extreme longevity while its installation time is slashed by over 30%, requiring no drilling or tools. This versatile base fits seamlessly between standing seams and is tested to withstand Category 5 hurricane wind forces. Added benefits include a protective rubber footing, economical shipment costs, and multi-directional adaptability for all your safety needs.

- USD

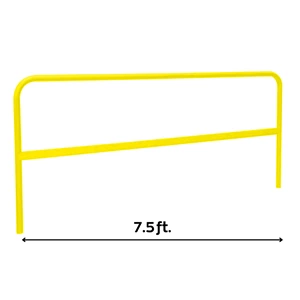

7.5 ft. Yellow Guardrial

70759

Tie Down's 7.5 ft. Universal Guardrail is designed with the needs of professionals in mind, providing a better alternative to active fall protection systems. With its powder coat painted safety yellow finish, the Universal Guardrail stands out as a highly visible safety measure on any job site. Its vibrant color enhances visibility, ensuring that workers can easily identify and navigate around the guardrail. One of the key features of the Universal Guardrail is its versatility. It is specifically engineered to fit over 95% of competitor bases available in the market. The multi-pin slot feature allows for easy adjustment and compatibility with a variety of bases from different manufacturers. This eliminates the need for specific or proprietary bases, making it a flexible and cost-effective solution. The Universal Guardrail provides exceptional freedom of movement, allowing workers to perform their tasks without hindrance. Unlike active fall protection systems that require harnesses and lanyards, this guardrail system doesn't restrict movement or interfere with the job at hand. Workers can work with ease and efficiency, maximizing productivity and minimizing disruptions.

- USD

Yellow 15 ft. Ladder Guardrail Corral

72884

Designed for fixed ladder access, this ladder guard system ensures the safety of ladder users by providing a protected and enclosed high-visibility barrier when climbing onto the roof and passing through swing gates. The clamp-on system attaches to the ladder's vertical rails and extends 15 ft. onto the roof, creating a barrier between the worker and the roof edge during ladder area entry or exit.

- USD

Tri-leg Folding Warning Line

65017

Tie Down's Tri-leg Folding Warning Line provides a quick set-up and tear-down warning line for commercial roofing projects. This heavy-duty pre-galvanized tubing and clear coat finish prevent rusting from the inside out. Each stanchion includes a retractable carry handle for ease of use. This complete kit includes four stanchions with 100’ of warning line pennants. Choose this durable and easy-to-use warning line system for your job site. Tie Down maintains high standards and quality control through quality raw materials and components made in the USA.

- USD

Yellow Universal Compression Clamp (UCC) Guardrail Base

71091

Tie Down Engineering stands as the premier manufacturer of passive systems, setting the industry standard for safeguarding building perimeters, stairways, and elevator shafts. Compliant with OSHA 1926.502, our Universal Compression Clamp Base Guardrail System is the epitome of seamless, user-friendly, and safe solutions. It seamlessly accommodates all upright guardrails on the market without the need for pins. Our innovative system installs effortlessly using an impact gun to tighten our Universal Compression Clamp, eradicating the common issue of wobbly, loose connections found in other systems. The UCC Base Guardrail System is designed to fit both 1.66 and 1.90 OD tubes, making it the most versatile and straightforward passive guardrail system for rooftop and job site applications. At Tie Down Engineering, we uphold rigorous standards and unwavering quality control, sourcing our raw materials and components exclusively from the USA.

- USD

Yellow Socket Guardrail Base Assembly

71094

Tie Down's Socket Guardrail Base stands out as the lightest guardrail base in the United States, weighing just 58 lbs. Its innovative design includes base plates that nest and stack efficiently, simplifying transportation and storage. Featuring convenient toe board slots and handle holes, this base reduces the risk of soft tissue injuries during handling on the job site. It comes with the option of a galvanized finish for enhanced durability and resistance. Suitable for both permanent and temporary applications, it meets OSHA 1926.502 and 1910 Subpart D standards, all without penetrating the roof substrate. The coating ensures extreme longevity while its installation time is slashed by over 30%, requiring no drilling or tools. This versatile base fits seamlessly between standing seams and is tested to withstand Category 5 hurricane wind forces. Added benefits include a protective rubber footing, economical shipment costs, and multi-directional adaptability for all your safety needs.

- USD