close

Filter By

Brand

Country of Origin

Division

Gross Weight (lbs.)

- 0.05 1

- 0.10 1

- 0.16 1

- 0.25 1

- 0.35 1

- 0.50 1

- 0.59 1

- 0.60 1

- 0.67 2

- 0.71 1

- 0.75 3

- 0.97 1

- 1.00 5

- 1.10 1

- 1.15 1

- 1.24 1

- 1.30 1

- 1.34 2

- 1.42 3

- 1.48 2

- 1.50 1

- 1.58 3

- 1.59 1

- 1.60 1

- 1.62 2

- 1.67 2

- 1.70 2

- 1.71 1

- 1.75 2

- 1.76 1

- 1.77 1

- 1.83 1

- 1.85 1

- 1.93 2

- 1.94 1

- 10.00 1

- 10.50 1

- 11.00 1

- 11.50 1

- 12.00 2

- 12.19 1

- 12.80 1

- 13.25 1

- 18.00 1

- 19.00 1

- 2.00 2

- 2.05 1

- 2.10 2

- 2.20 1

- 2.25 1

- 2.32 1

- 2.50 1

- 2.53 1

- 2.80 2

- 22.00 1

- 3.00 1

- 3.08 1

- 3.10 1

- 3.15 1

- 3.48 1

- 3.50 2

- 3.75 1

- 3.80 1

- 3.85 1

- 3.98 1

- 37.00 1

- 4.00 1

- 4.02 1

- 4.50 2

- 4.60 1

- 4.73 1

- 5.00 2

- 5.13 1

- 5.20 1

- 5.30 1

- 5.60 1

- 5.67 1

- 5.94 1

- 56.00 1

- 6.00 1

- 6.03 1

- 6.25 1

- 6.34 1

- 6.50 7

- 7.00 4

- 7.44 1

- 7.50 2

- 7.67 1

- 7.97 1

- 8.00 2

- 8.17 1

- 8.20 1

- 8.67 1

- 8.80 1

- 9.00 2

- 9.50 1

- 9.67 1

- 90.00 1

- 95.00 1

Warranty

Width (in.)

12.80, 8.00, 0.25, 6.25, 7.44, 5.60, 1.75, 9.00 - Manufactured Housing

11 items

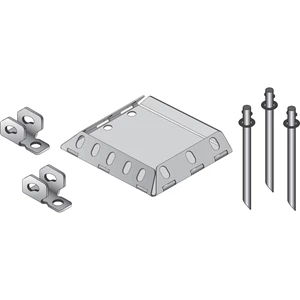

ANGLE FRAME BRACKET

59009

Crafted from high-quality steel, Tie Down's Angle Frame Bracket serves as a pivotal connection point, ensuring a robust foundation for your structures. Designed for the attachment of longitudinal anchors to I-beams at both ends of the home, the Angle Frame Bracket is a fundamental component for anchoring security. With a 1-year warranty, Tie Down's commitment to quality is evident in the durable construction of the Angle Frame Bracket. Prioritize safety and stability by strategically determining anchor and stabilizer plate locations, along with bracket placement on the I-beam. Ensuring a strap angle of 60 degrees or lower optimizes the effectiveness of your anchoring solution. The installation process is straightforward: Drill a ½-inch hole centered in the I-beam, at least 4 inches from the edge. For wind zones II and III, connect two frame brackets with a ½-inch grade 5 bolt and nut; for wind zone I, one frame bracket is sufficient. Attach the swivel connector and strap to the angle frame brackets using ½-inch grade 5 bolts and nuts, then tighten securely.

- USD

37 ft. G60 Galvanized Strap

59155

Tie Down's Galvanized Steel Strap is engineered to meet the stringent requirements set by HUD Codes 3280 and 3285(2). Crafted from high-quality galvanized steel, this strap is designed to provide superior strength and durability for your mobile home anchoring needs. Conforming to ASTM D3953-97 standards for strapping, flat steel, and seals, this Type 1, Grade 1, Finish B steel strap boasts a minimum total capacity of 4,725 lbs. and a working capacity of 3,150 lbs. Its exceptional load-bearing capabilities ensure reliable and secure anchoring for your valuable property. For added convenience during installation and monitoring, the strap is conveniently marked every 5 ft., allowing you to easily measure and position it accurately. Tie Down's Galvanized Steel Strap is built to withstand the elements, offering reliable protection against weather deterioration and corrosion. The galvanized coating provides equivalent weather resistance to zinc-coated steel, ensuring the longevity and integrity of the strap even in challenging outdoor conditions.

- USD

8 ft. G-120 Strap with Swivel Connectors, 50 per box

59213

Tie Down's Universal Swivel Strap Connector empowers you to achieve secure bolted swivel or slotted clip attachments by seamlessly connecting straps to beam clamps and uplift brackets. Crafted for excellence, these connectors are made with G-120 strap material, ensuring exceptional strength and durability. Offering a comprehensive range of installation options, you have the flexibility to choose between swivel strap and I-beam bracket connections, sidewall slotted configurations, sidewall setups with nut and bolt fasteners, and longitudinal I-beam installations. Engineered to meet the demands of wind zones 2 and 3, Tie Down's Universal Swivel Strap Connector excels in challenging conditions, ensuring reliable performance in diverse construction environments. Each package includes one high-quality strap and is available in quantities of 30 or 50 per box or 8 per bundle of connectors.

- USD

500 lb. Holding Power All Purpose Light Duty Anchor Kit

59070

Tie Down’s versatile All Purpose Light Duty Anchor Kit is specifically designed for light-duty use, making it perfect for tasks that require up to 500 lbs. of ultimate holding power on each anchor. The kit includes four 15 in. painted anchors, each boasting an impressive 500 lbs. ultimate holding power. These anchors are strategically placed on corners, providing stability and security. The inclusion of eight 1/8 in. galvanized clamps further reinforces the setup, ensuring a robust and dependable connection. To further enhance its utility, the kit offers 50 ft. of 1/8 in. galvanized aircraft cable. This versatile cable can be cut to the desired length, allowing you to connect anchors together or use them individually. The cable’s galvanized construction ensures durability and resistance to corrosion, ensuring its reliability over time.

- USD

Soil Test Probe Kit

59200

Tie Down's comprehensive Soil Test Probe Kit includes high-quality tools and accessories that enable precise and thorough soil testing. The probe's exceptional ability to penetrate the ground and retrieve soil samples provides valuable insights into soil composition and properties. Its compliance with NCS BCS A225.1 (ANSI A119.3) and HUD specifications ensures that you're using a high-quality, reliable tool that adheres to industry standards. Maximize anchor holding strength by using the Soil Test Probe Kit to identify the optimal anchors for specific soil conditions. This proactive approach ensures the stability and durability of your anchoring systems, enhancing the overall performance of your projects. By utilizing the Soil Test Probe Kit to make informed decisions about anchor selection, you can understand the soil conditions, which helps prevent anchor failure and ensures the long-term stability of structures, ultimately increasing project safety and reliability. All components are conveniently stored in one place with its multi-pocketed carrying case, making it easy to transport the kit to various job sites without any hassle.

- USD

24 in. x 24 in. ABS/PLASTIC FOUNDATION PADS for block and steel piers, 4 sq. ft.

59303

Designed to be placed under and support piers that hold up your mobile home, Tie Down's ABS Foundation Pads offer an innovative and efficient solution for your foundation needs. These pads are lighter than traditional concrete, leading to labor and cost savings during installation. With larger pad sizes, they increase spacing, saving valuable time and materials. Environmentally conscious, these foundation pads are made from recycled materials, contributing to sustainability efforts. Their stackable design allows for easy expansion, creating larger pad areas and wider pier spacing, ideal for various applications. Intended for use with either block or steel piers, the ABS Foundation Pads come in both single and multi-pad configurations, catering to different soil capacities. They are approved for use by HUD 3285.312(3) and are listed and labeled by RADCO #1345, ensuring compliance with industry standards.

- USD

4 in. x 6 in. x 1 in. PADS AND PIERS ABS SHIMS/WEDGES

59663

Tie Down's ABS Shims/Wedges, measuring 4 in. x 6 in. x 1 in., are expertly crafted to deliver impeccable support and alignment in pier structures. These shims excel in filling gaps and securing piers between the pier plate and main beam, ensuring a solid and level foundation for your structure. Precision is paramount. Whether it's leveling your home or bridging gaps between the base of the main beam and the top of the pier cap, our ABS Shims/Wedges deliver the perfect solution. Installation is straightforward and hassle-free. Following the placement of an 8" x 8" x 16" concrete block atop pier footings, determine the gap size between the pier and beam. This measurement dictates the number and size of shims required (minimum of 2 inches), maintaining a clearance of less than 1 inch between pier top and beam bottom. Our shims can be double-stacked—2 inches on 2 inches or 1 inch on 2 inches—to adapt precisely to your needs. For double pier plate stacks, conveniently position two cap plates side by side. ABS Shims/Wedges must be used in pairs, ensuring a reliable and uniform support system for your pier structure. Fully approved for use by HUD 3285.312(3), attesting to their superior quality and adherence to industry standards, our ABS Shims/Wedges are thoughtfully crafted from recycled ABS materials, aligning with environmentally friendly construction choices.

- USD

STEEL PIER SET for XI2 ASPHALT SYSTEMS

59616

Xi2 Asphalt Foundation System for Manufactured Adjustable Steel Piers

- USD

Perimeter I beam Frame Kit

59617

Xi2 Asphalt System Hardware Kit for Perimeter I beam Frame

- USD